Brian Peoples, who operates a drone spraying company out of Brenham, is also an aviation pilot. He started flying his radar and lidar drones during downtime at the airport. Sarah Beal photo

Bluebonnet-area farmers combine their instincts and experience with apps, artificial intelligence, data, drones and advanced equipment to yield better crops and more efficient care for cattle

Story by Addie Broyles * Photos by Sarah Beal

As farming technology advances, Emory Thomas looks forward to the future. He also wants to keep driving his truck.

Thomas is the second-generation owner of a turfgrass company with several farms in the Bluebonnet Electric Cooperative service area. He grew up in North Texas, where his father and grandfather were originally dairy farmers. They moved to Central Texas and transitioned to growing sod in the late 1960s.

It was a family affair with all three of his brothers working at the company until his dad sold it in 1999. Thomas eventually started Thomas Turfgrass, which he now runs with his wife, Sandy, and their two children, Seth Thomas and Traci Thomas Claughton.

In some ways, the process of growing turfgrass and cutting it into squares or rolling it into mats hasn’t changed much in recent decades, but technology today results in a more efficient and automated process.

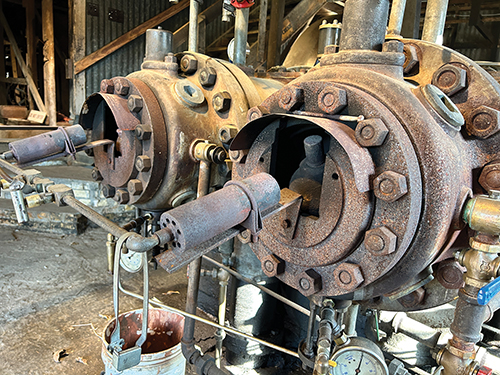

Until a few years ago, Thomas Turfgrass used a harvesting machine that required two people to stand on the back and stack sod onto a pallet. Now they use a machine with a robotic arm that can move five rolls of turf at a time onto pallets that can hold 35 rolls each — all while the harvester is moving. That machine and their mowers are all guided by built-in GPS systems that keep them from overlapping when they mow, Thomas said.

The next big investment will likely be an autonomous mower that can cover 25 acres per hour, but Thomas said they won’t rush into it. “You can tie a lot of money up real quick buying new equipment,” he said, adding that they will wait until “all of those bugs are worked out before we try it.”

Thomas embraces technology and is always learning, even if it doesn’t come naturally to him. “If I have a problem with my phone, I may work on it for three hours; then my daughter will straighten it out in three seconds,” he said. “I learn as much as I can as fast as I can, but my daughter and my son have to educate me frequently.”

Even with equipment that reduces the number of people needed to harvest grass, he still needs 80 workers at the height of the summer season, Thomas said.

He envisions a future where his operations will be completely autonomous, he said, “but in my mind, that’s only a dream.”

Which is just as well, because Thomas doesn’t plan to give up driving. “We look forward to that.” he said.

The best tech tool is in farmers’ pockets

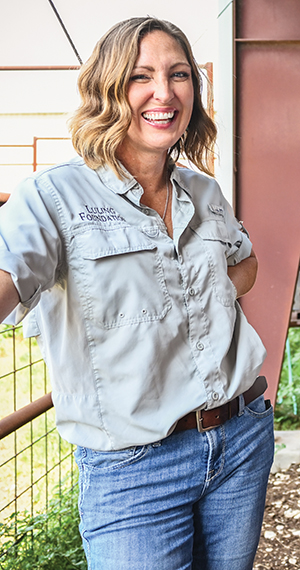

Despite the availability of expensive new high-tech equipment, the most significant technological advancement available to farmers across the Bluebonnet service area is likely already in their pockets, said Bonnie Dredla of the Luling Foundation, a teaching farm in Caldwell County.

Smartphones offer numerous apps, like Weather Underground for precise forecasts and Acres for buying and selling farmland.

The 406 Bovine app is one of Dredla’s favorite (and cheapest) tools to show visitors at the teaching farm. Farmers can scan the face of each cow in their herd and use facial recognition to identify them, much like technology used for humans at airports.

A standard smartphone can even help a farmer find a low spot in a field or make sure a fence is level.

Dredla has learned a lot about the needs and concerns of farmers in her 20 years managing the foundation. It was founded in 1927 by Luling oil wildcatter Edgar B. Davis and is now a 1,100-acre farm that hosts visitors from around the world who are interested in newer technologies and strategies for living off the land sustainably.

Dalton Merz, Dredla’s 82-year-old father, is a lifelong farmer and former rangeland management specialist with the Natural Resources Conservation Service. He uses his smartphone to identify plants today.

While the past 20 years have seen an abundance of new technology and tools, it can take a long time for them to be widely adopted, said Wayne Morse, Caldwell County Texas A&M AgriLife Extension agent, who grew up not far from the Luling Foundation.

Economic and environmental pressures factor heavily into farmers’ decisions to adopt new tech tools, Morse said. The size of an operation, as well as droughts, predators, pests or poor yields can increase interest in new equipment and devices.

This year, spring rains in the Bluebonnet region eased some concerns about a prolonged drought, but the prices of essential materials such as fertilizer and feed have remained high, Morse said. Technology may help farmers use less fertilizer, but it won’t make that fertilizer any more affordable. “Technology isn’t going to save us,” Morse said. “You still have to adopt good farming practices alongside it,” like rotational grazing and crop diversification.

According to the USDA’s 2022 Census of Agriculture, Texas lost about 1.6 million acres of farmland between 2017 and 2022, yet statewide income from farm-related sources grew by 64% during that time.

Those numbers vary widely in the Bluebonnet region. While total farmland acreage declined in many fast-growing counties in the cooperative’s service area, it increased in Lee, Gonzales and Washington counties.

In Texas, where cattle production remains one of the largest sectors of the agricultural industry, ranchers have embraced ultrasound scanners that can show the size of the ribeye and the marbling of the fat while the animal is still grazing in a field. Another older but still widely used tool is EPD, or expected progeny difference, a formula and rating system to estimate the genetic value of cattle for breeding. DNA analysis has made these ratings more precise.

“We had to go from our old-school way of thinking about livestock to looking at the genetic profile,” said Morse, who grew up in Kingsbury and participated in livestock judging competitions from elementary school through his years at Blinn College and Texas A&M University.

“A bull might not look the best,” he said, but its EPD score might show otherwise.

Drones expand farmers’ and ranchers’ horizons

Drones of all sizes have buzzed their way into the toolkits of many Central Texas farmers and ranchers. Aerial images of farmland that could once only be taken from helicopters or prop planes can now be captured with a small $300 drone.

Larger, more sophisticated and complex drones can precisely spray fertilizers and pesticides, measure and monitor land or keep track of livestock. There are drones equipped with radar, thermal and lidar (laser imaging, detection and ranging) technology that can measure soil moisture, canopy coverage, germination and plant growth rate.

“Drone technology has made leaps and bounds, and people are adopting it,” Morse said. “People finally understand the data that we have access to.”

Prices for precision drones can top $20,000, so some Bluebonnet service area farmers are contracting the work to trained, skilled owners of specialized drones.

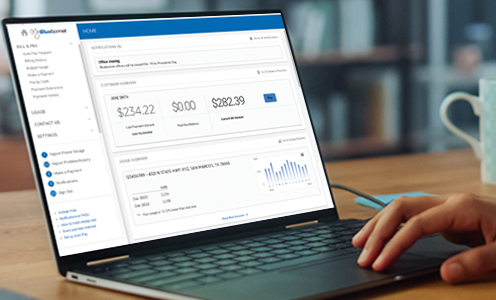

Brian Peoples of Brenham is one of those specialists. The retired police officer and corporate pilot grew up and then worked in farming and ranching in Washington County. He saw an opportunity to bring lidar- and radar-enabled crop dusting to the area, and last year, he co-founded Independence Aerial Solutions with his wife, Lisa Peoples. Their drones help local farmers map and spray their fields and monitor their livestock.

Like advanced drones, other technology innovations can create new jobs and eliminate dangerous on-the-ground work.

For example, the hydroponic farming company Inevitable Technology — formerly Iron Ox — uses robots to move heavy containers of water at its 12,000-square-foot indoor growing facility on the eastern edge of San Marcos.

Since the 1990s, row-crop farmers have embraced GPS technology to make sure their furrows are straight. The newest high-tech tractors have devices that do much more, such as analysis of soil composition and moisture. That allows every seed to be planted at exactly the right depth. The most expensive tractors on the market have machine-learning-based navigation and can work in tandem with drones and satellites — but they can easily top $500,000.

Besides, repairs of high-tech tractors are expensive and time-consuming. "Farmers used to be able to fix their tractors with just a few basic mechanical skills, but that's different now," Morse said.

From artificial intelligence to food-treatment technology

Another major technological advance in the past decade has been the advent of artificial intelligence. Commonly used online AI tools such as ChatGPT can help with the administrative side of running a farm, from creating and analyzing spreadsheets to tracking weather and market forecasts.

Despite new technology and online tools, humans are still essential to agriculture, said Ali Fares, a professor at Prairie View A&M University who specializes in the intersection of water and food.

He and his team have used AI to process results they gleaned from studying farmland using thermal drones, ground-based sensors and satellites. That technology gathered data about a farm’s water use, soil condition and health of its plants.

One day, Fares hopes more artificial intelligence analysis will be available to farmers on a smartphone app. From the app, a farmer could learn ways to treat and prevent problems. For generations, farmers have known about amending and improving soil, but such precision monitoring and reporting technology could give them valuable new information.

“We want to help farmers take advantage of whatever technological opportunities are available,” said Fares, who has worked with farmers for more than a decade. When they see the results of a new piece of tech, whether at a neighbor’s farm or an extension service’s outreach event, they are interested in using it, he said.

“At the end of the day, farmers are businesspeople,” Fares said. “They need to make a living so they can have a life.”

While some high-tech agricultural workers fly drones, others work under microscopes.

Gary Beall worked in nanoparticle research for decades and taught chemistry and biochemistry at Texas State University in San Marcos. He developed barrier technology to create an edible, protective layer — made of clay and a polymer extract from a tree — that extends the shelf life of fruits and vegetables.

In 2021 he co-founded Nabaco, a company based east of San Marcos, to produce the barrier called NatuWrap. The company worked with fruit orchards in states in the Northwest U.S., California and Hawaii to coat cherries, pears, apples, oranges, lemons and limes. Nabaco’s headquarters are in the Bluebonnet Electric Cooperative service area.

Although many forms of ag technology are aimed at increasing production, Beall’s goal is to reduce food waste. About 30% of all fruit grown goes to waste, he said.

Despite new tech, product innovations and smartphone apps, nothing can replace knowledge handed down from one farming or ranching generation to the next, Dredla said. “You can’t replace someone who has spent a generation in the field analyzing cows with a science that can count the parasites,” she said. “A lot of being successful is understanding the history and not repeating things that didn’t work in the past.”

Farmers and ranchers are stewards of the land. They’ve learned the dangers of overapplying chemicals, and the importance of conserving water, protecting beneficial insects and maintaing a conservationist mindset.

Morse grew up hearing these messages from farmers who didn’t have drones to check the ID tags on their cows’ ears.

“There will never be a replacement for the hands-on nature of this business,” Morse said. “It turns out that you can’t learn everything on YouTube.”

***

OTHER VOICES FROM THE BLUEBONNET REGION

Derrick Smith

Bulls Eye Ranch

BURTON

Derrick Smith, owner and operator of Bulls Eye Ranch and Bulls Eye Products and Concrete, has been around ranching his entire life. He learned a lot from family and 4-H as a kid. Now he runs the business, sells champion cattle and travels internationally to judge livestock.

Artificial insemination of his cattle is the technology with the biggest impact on his ranch. A microscopic vacuum extracts eggs from cows that are then combined with “reverse-sorted” semen — processed to select for female-producing sperm — to produce female embryos. “We were the first to reverse-sort Brahman semen in the United States,” Smith said. He relies on online cattle management software to keep up with daily details. The TagMax by CattleMax app allows him to track when a cow is in heat, when a calf is born and which cows are in which pasture.

Greg Fryer

Rivers Edge Cattle Company

WINCHESTER

Greg Fryer grew up around cattle and has worked in the agricultural industry for more than 20 years. His wife Mindy’s family owned the land where Rivers Edge Cattle Company now raises its primarily Brangus herd and offers custom hay baling. Over the years, Fryer has taken advantage of improved technology to produce and bale hay. He relies on GPS technology when planting, spraying and fertilizing fields. The Raven spraying and EZ-Pilot guidance systems on his New Holland tractor can map where crops have been planted or sprayed, making the process more efficient, he said. Looking ahead to agriculture’s next few decades, Fryer envisions more use of automated systems and drones.

***

Laser scarecrows and robotic harvesters? Possible future farming technology

From robotic harvesters to laser scarecrows and blockchain hay bales, tomorrow’s farms may rely on a host of emerging technologies now being tested, imagined and refined in labs and pilot fields across the country.

These are just a few of the technologies that could shape the future of farming.

- Robotic harvesters and robots that seed or weed are in development.

- Controlled environment agriculture, including indoor farming, will become even more automated.

- Minichromosomal technology may be used to create different traits in plants to improve resilience, crop yield and quality.

- Bee vectoring, a precision agriculture system, uses bees to disseminate naturally derived pesticides to flowering crops.

- Laser scarecrows, developed by researchers from the University of Rhode Island and Cornell Cooperative Extension, use moving laser beams to frighten birds away from fields.

- Zero-waste and regenerative farming is a type of ecosystem-based agriculture that focuses on improving the soil and reducing waste. It includes practices like crop rotation, bringing animals into the farming system, and using fungi and algae to refresh the soil naturally.

- Precision planting equipment, guided by a GPS system, tracks placement and spacing of seeds to ensure uniform crop growth and yields.

Sources: Texas A&M AgriLife, Farm Progress

***

Farmers’ tools have evolved with every generation

Farmers have been creating and improving their tools since the birth of agriculture, about 12,000 years ago. The earliest agricultural tools in Texas were made by indigenous people from sticks, deer antlers, bison bones and freshwater mussel shells. When European settlers arrived in the Bluebonnet region in the 1800s, they used oxen and horses to pull wooden plows and harvested crops by hand with sickles and flails — two connected wood sticks used to thresh grain.

The late 1700s and early 1800s brought new cast-iron plows with interchangeable parts and mechanical harvesting tools, such as the mechanical reaper and John Deere’s self-scouring steel plow. That made it easier for Texas farmers to cut through the nutrient-dense, clay-heavy soils of the Bluebonnet-area’s Blackland Prairie.

The Homestead Act of 1862 accelerated westward migration, increasing demand for efficient farming tools: windmills to allow farmers to dig deeper wells and barbed wire fencing to create large, enclosed pastures.

As cars started to fill American cities after 1910, gasoline-powered tractors began arriving on Texas farms. By the 1940s, they replaced most animal labor. The Rural Electrification Act of 1936 brought electricity to remote farms and ranches, ushering in an era of machines such as irrigation pumps and mechanical threshers. After World War II, large-scale farms introduced chemical fertilizers, cultivators to break up soil, planters to drill wide swaths of seed, and combines to cut, thresh and clean grains in a single process. Bigger fields were planted faster.

Starting in the 1940s, biotechnology brought about artificial insemination for livestock on ranches. The satellite-based Global Positioning System, launched for military use in 1973, became available to the public in the late 1980s, making agricultural mapping, planting and harvesting on farms more accurate.

One trusty printed tool that has remained in ranchers’ and farmers’ pockets for more than 230 years has stayed relatively unchanged.

The Old Farmer’s Almanac — an annual publication that includes weather predictions, harvest timetables, lunar cycles and sunrise times — has been printed since 1792. Nevermind that studies find the almanac’s weather predictions are correct about half of the time: Many of today’s farmers still turn to the book for guidance. It is online today, too, at almanac.com.

Sources: Texas State Historical Association, American Society of Animal Science

***

Farm Safety Week, year-round awareness

Farm Safety and Health Week is Sept. 21–27, a time to recognize the importance of safety in agriculture and raise awareness about the hazards farmers face every day. While this designated week serves as an important reminder, safety on the farm should be a year-round priority.

Farm accidents involving equipment and utility infrastructure can result in injuries, deaths and power outages. Among the most common incidents are collisions between tractors or other machinery and power lines or utility poles. While these accidents can have serious consequences, many are preventable with caution, awareness and safe operating practices.

Farm electrical safety tips

- Maintain a safe distance. Keep at least 10 feet of clearance from all utility equipment in all directions.

- Use spotters and flags. Spotters and visible markers provide guidance and awareness to help farmers safely navigate around electrical hazards.

- Know what to do if you make contact. If your equipment touches a power line, stay inside and call 911.

- Treat all equipment as conductive. Materials such as lumber, hay, tree limbs, irrigation pipes and bulk goods can carry electricity — keep them away from power lines.

— From the National Rural Electric Cooperative Association

See this story as it appeared in the September issue of TCP magazine here.