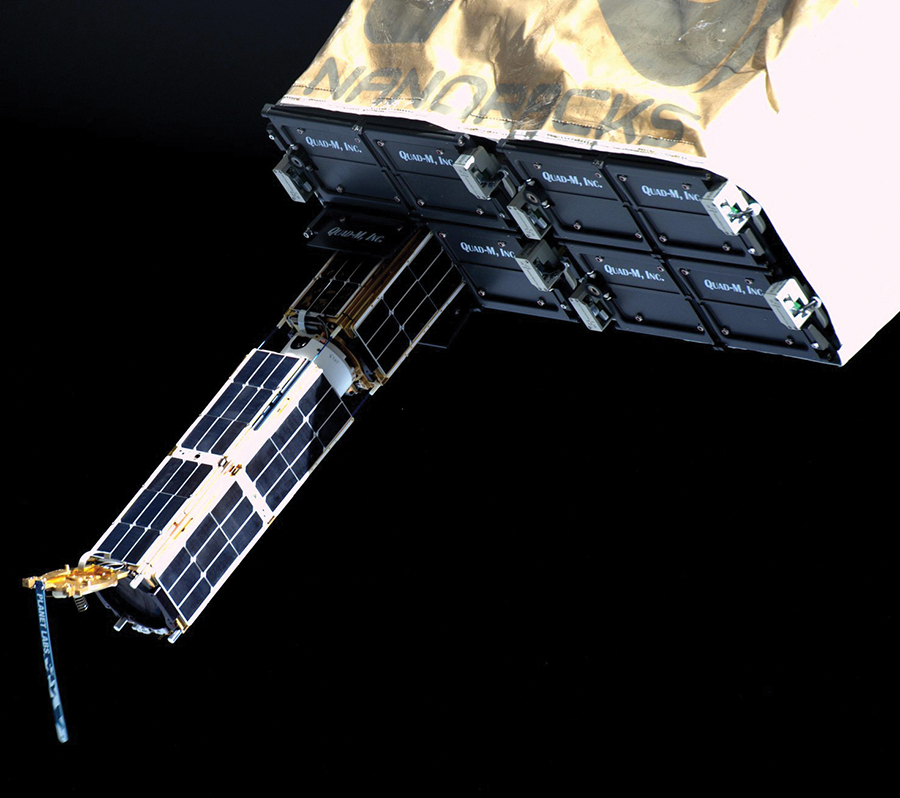

The Cygnus spacecraft, high above Florida with a view toward the south, in 2017. The darkened rectangular metal device on its bottom left holds a cube satellite dispenser designed and built by Quad-M. Photo courtesy NASA

In an unassuming building amid farmland near McDade, the small manufacturing company Quad-M is creating high-flying systems for use in space

By Melissa Segrest

The rural landscape about a mile west of the community of McDade cradles an unlikely business. The aerospace engineering and manufacturing firm Quad-M has turned its little piece of northern Bastrop County countryside into a field of outer space dreams.

There’s no sign outside the company’s nearly windowless, cream-colored metal building on narrow Old Highway 20, just a stone’s throw from traffic hurtling along U.S. 290. Farm buildings dot the landscape. On a recent workday, a couple of Chevy Silverados and low-key SUVs sat in the small caliche parking lot. There are no flashy sports cars here.

Thanks to Victor Dube, McDade students made, watched launch of their own cube satellites »

More aerospace businesses in the Bluebonnet region »

The 8,000-square-foot facility looks as if it could house farm equipment, not high-tech machinery. But you can’t judge a cutting-edge space company by its terrestrial shell.

What starts here ends up 250 miles or higher above the Earth.

Inside the building, Quad-M’s team of nine full-time engineers, machinists and other skilled employees create devices for out-of-this-world experiences. They design, manufacture, test and assemble systems that hold, then eject, very small satellites into low-Earth orbit from the International Space Station or from rockets, including SpaceX’s Falcon 9 and spacecraft such as Northrop Grumman’s Cygnus. Its in-demand aerospace systems have deployed more than 300 cube satellites, or CubeSats, on more than 20 launches.

The company’s inventive devices have helped speed the pace of pushing these multifaceted mini-satellites into space. Quad-M is a 21st century ideas-into-space-delivery business.

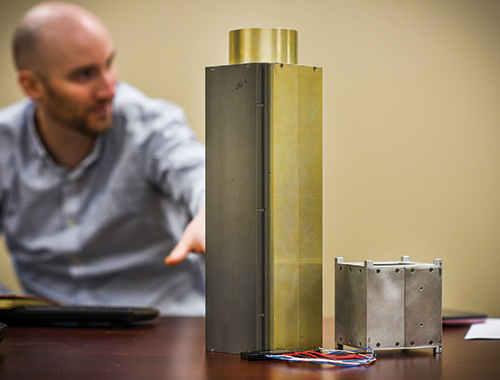

The smallest one-unit CubeSat is about 4 inches square, weighs only a few pounds and can sit in the palm of your hand. Quad-M’s hardware and devices vary in shape and size to hold different-sized CubeSats. A typical Quad-M dispenser holds 3-unit satellites — a few inches longer than a loaf of bread. The biggest CubeSat dispenser the company built can hold a 16-unit satellite.

CubeSats aren’t the only payload Quad-M’s systems can shoot into space: employees are currently fabricating a deployment system for a device weighing over 1,600 pounds.

Cube satellites are used by research students, scientists, governments or private companies for communication, technology testing, research and Earth observation. The small satellites study the planet for a multitude of reasons: to monitor weather patterns, measure solar flares, assess disasters like floods or fires, plan roads or maritime transportation lanes, examine environmental concerns, and strengthen military defenses and border security.

Commercial users deploy CubeSats for tasks as varied as studying parking lot activity at stores and helping farmers with their planting. Two CubeSats were sent by NASA to soar above Mars in 2018.

Commercial needs for the small satellites — which are exponentially less expensive to build and launch than their earlier counterparts, some of which weighed in at more than a ton — have created a growing and lucrative field.

Most of Quad-M’s aerospace competitors are big companies with equally big budgets. But bigger isn’t always better. In fact, it can be slower, more expensive, less flexible and not as innovative. And Quad-M — now employee-owned — continues to innovate, fueled by the vision and drive of its late founder, McDade native Victor Dube.

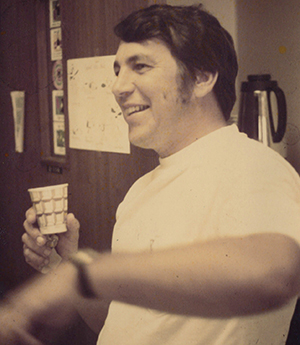

Dube was born in Elgin in 1941 and grew up in a log cabin on a cattle farm. At Elgin High School, one counselor told him he was “not college material.” Despite that pessimistic prediction, Dube earned a bachelor’s degree in mechanical engineering from The University of Texas at Austin and a master’s degree in civil engineering from Marquette University in Wisconsin.

In 1972, he started working at Austin-based Tracor, a defense electronics contractor. There, Dube helped develop countermeasure defense systems for aircraft and missiles. After Tracor, he founded Quad-M in 1989 and first tried his hand at building superchargers that could quickly add extra horsepower to vehicles.

The name Quad-M was probably a reference to the four manufacturing machines the company had in its early days, said Bob Picard, who started working with Dube in 1990 and now is the company’s shop foreman.

Dube dreamed of developing aerospace technology and made that shift at Quad-M in 2012.

The company’s big space breakthrough came in 2014. Dube worked with Mike Johnson, co-founder of Nanoracks, a service provider for space missions, to design and build the first commercially operated device to deploy cube satellites from the International Space Station. That system, which is still in use, has launched more than 300 CubeSats from the crewed space station orbiting 250 miles above the Earth.

When propelled into space from a metal chute, the satellites resemble long shoeboxes, dwarfed by the massive station.

You can watch a video of a 2014 deployment in action on YouTube, at bit.ly/3mz6zxU.

From that beginning, Dube and his team created a variety of systems to shoot satellites into space.

Working in conjunction with Johnson’s next company, SEOPS, Quad-M created the Slingshot system to attach to the front of a Cygnus cargo spacecraft. After separating from the space station, Cygnus can travel another 80 miles higher in orbit before ejecting CubeSats. That extra distance helps the satellites stay in orbit longer.

Dube and his co-workers even patented a new type of leaf spring that can fold flat to eject satellites with plenty of force. They also did miscellaneous non-aerospace manufacturing when time allowed.

While at Quad-M, Dube found time to instill interest in rocket science with a few far-reaching projects for McDade ISD students. (See story, Page 23.)

Dube died at 80 on Jan. 24, 2022. His wife of 56 years, Judith Dube is a retired teacher and still lives in the McDade area. Their three children have had accomplished careers: Mark Dube is a mechanical engineer at BAE in Austin (formerly Tracor), Shawn Dube is an electrical engineer at Dell and Michal Dube, who worked as operations manager for Quad-M for several years. There are 10 grandchildren.

“Victor's guidance, kind nature and formidable engineering abilities were outstanding examples to follow for anyone lucky enough to work with him,” said Tyler Holden, who joined the company in 2014 and became Quad-M’s CEO in 2022. “It was an absolute privilege to learn from him for so long, and I consider myself extremely lucky to have had the chance.”

Holden, 36, of Bastrop, is originally from Maine. He credits the encouragement of a high school teacher for his initial exploration of 3-D computer-aided design. With a bachelor’s degree in electromechanical engineering from Vermont Tech and some work at a big company under his belt, he came to Texas looking for a job in the aerospace industry.

He liked Victor Dube, Quad-M’s size and the fact the company had its own machine shop. “You learn a lot about design from the machinists and an experienced engineer like Victor,” he said.

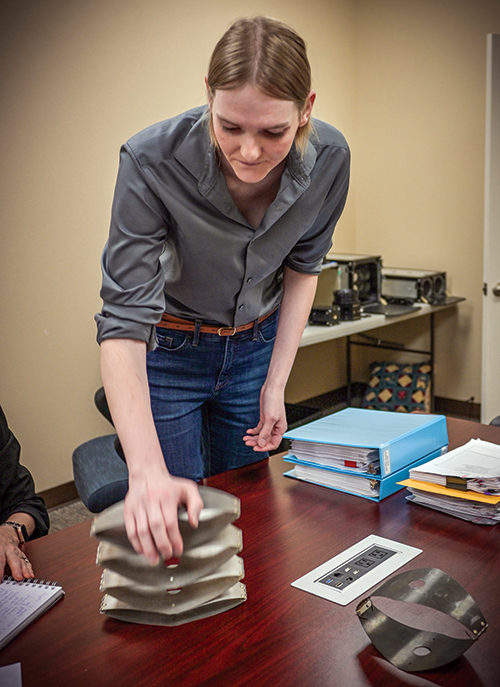

Alex Kuehn is the company’s 28-year-old vice president of engineering. She grew up in Wisconsin, studied aerospace engineering in Arizona, built prototype aircraft in Minnesota and worked briefly at a small rocket propulsion company in Utah before talking to Dube in 2018. “I knew the opportunity to work on stuff that would go to space was too good to pass up. So I packed up my life and moved to Texas.”

Today, she focuses on product design and analysis, business development of Quad-M and helping establish the new Xterra line of aerospace products.

She, too, spoke of Dube’s impact on the company and the industry.

“Victor was an innovator, a dreamer and an exceptional engineer, but most importantly, he was a great person who took care of people,” Kuehn said. “By the time Victor passed away, he was largely responsible for deploying more satellites than any other single individual we’re aware of.”

Gina Reat of Giddings, Quad-M’s president, has worked there seven years. “If it’s not engineering or machining, it’s my job,” she said, “which means accounting, purchasing, receivables, human resources, janitor and whatever else needs doing.”

“When Victor passed away we were all devastated. Not only did we lose our boss, but a leader, friend, father figure and encourager,” Reat said. But Quad-M employees kept going. “That’s when we realized the importance of the legacy Victor left us. We are still in business because he created a culture of training and teamwork.”

Bob Picard of McDade, shop foreman and quality manager, started working with Dube in 1990. “I’ve done every job in the shop: training new employees, programming, setting up and running all the machines,” he said. Chris Moore of Bastrop, the production manager, started in 1996.

There are two other machinists, and a new engineer started last year. As of late April, Quad-M had a job opening for another engineer.

In addition, a small number of contractors bring specialized skills in software, aerospace, mechanical or electrical engineering to Quad-M’s components.

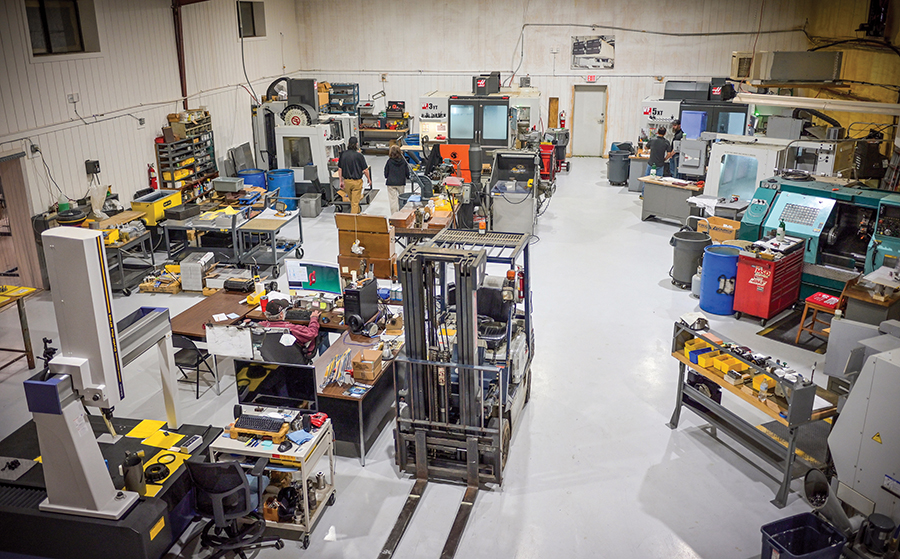

Inside Quad-M, projects usually start in the engineers’ room. Each works in front of multiple screens, converting what may begin as a sketch of a rough concept into detailed 3D renderings of components.

The action then moves to the 4,000-square-foot machine shop, where machinists operate four computer-programmed milling machines and two lathes that precisely control the shaping and shaving of aluminum or stainless steel pieces destined for space.

The shop’s white floor suggests laboratory cleanliness, while barrels of metal filings are a reminder that this work is as tough as it is sophisticated. Several employees who operate the machines learned to manage the production processes under Dube’s watchful eyes.

Precision is essential, so a measuring machine compares finished pieces to engineers’ requirements. Some features must be accurate to within .0005 of an inch. A fine human hair, by contrast, is about .0015 of an inch.

The final in-house steps for hardware happen in the assembly area, which grew to 3,000 square feet in 2019. There, employees scrutinize finished pieces, some of which have just returned from outside vendors after receiving specialized coatings to reduce friction or damage from space travel. Hardware and parts are cleaned and assembly begins.

Sensors and cameras allow employees to test how a satellite will move or tilt when it flies out of a dispenser. Quad-M employees take their hardware to facilities in Austin, Houston, Dallas or California to undergo testing for launch readiness. That includes tests to withstand extreme vibration and sudden rapid acceleration or deceleration. “The force of, say, a car smashing into a wall, or more. It can be pretty aggressive,” Kuehn said.

Now, new cutting-edge components are being created under the brand of Xterra, Quad-M’s recently formed parent company. Xterra has four patents pending on new aerospace products, Kuehn said.

More potential customers are reaching out to Quad-M as its reputation grows.

For now, though, the company will stay tucked away on Old Highway 20. There’s still some room to expand in the metal building, although eventually a new, larger facility will probably be needed.

Holden and Kuehn hope the company will continue to grow, but not too fast.

The group maintains Dube’s vision, that a smaller team is better. Jobs they finish in months would take years for bigger companies to complete, they say. “We’re probably the smallest company that does this,” Holden said.

“There are times we’re working on stuff and we say ‘Gosh, I wish Victor were here to see this,’ ” Kuehn said. “I think he would be proud of what we’re doing now.

“On some level he wanted to show the aerospace industry what we could do. That we have all these capabilities.”

Being part of the space industry was exciting for Dube and his team. Whenever they had the chance, employees would gather to watch live video of their equipment shoot satellites into space.

Today is a time of big ideas about the evolution of space exploration. The Artemis program includes plans to return humans to the moon in 2025, using NASA’s Orion spaceship and Space X’s massive Starship, which is the most powerful rocket ever to fly. A planned permanent base on the moon would set the stage for humans’ first mission to Mars.

Quad-M’s employees think about the possibility of sending devices far enough out to orbit the moon, Mars and maybe even Venus. “I’ve always wanted to set altitude records,” Holden said.

Do aerospace engineers dream of going into space?

“Is it always in the back of my mind? Yeah,” Kuehn said.

“Yeah, I do,” Holden said. “I wouldn’t think twice about it. My wife would probably yell at me, but, yes.”

No one recalls Victor Dube saying he would like to go into space. He was a practical man whose vision was for the world to discover the aerospace breakthroughs taking place in the building off Old Highway 20.

That’s how he probably wanted Quad-M to continue: Onward and upward.

***

Thanks to Victor Dube, McDade students made, watched launch of their own cube satellites

By Melissa Segrest

Victor Dube, the founder of Quad-M, loved his hometown of McDade and its very small school district of about 330 students.

He wanted to give students a taste of creating something for outer space, just like the engineers and machinists were doing at his company. So he helped them build cube satellites, one of which was later ferried by a SpaceX rocket to the International Space Station, for launch into low-Earth orbit — a school project for the cosmos.

“The first year he went to the McDade school to recruit students, the high school students didn’t want to give up their summer,” said Judith Dube, Victor’s wife. “So the middle school students took part.”

Colby Miller was 9 when he started working on the project in 2018. “When Colby wanted to go back to school in the summer, I had to wonder what he was up to,” said Joey Miller, Colby’s father and a member of the McDade ISD School Board. “When he told me they were building a satellite, I said ‘Don’t get me in trouble here.’ ”

Colby and eight other students — all in middle school — worked through that summer and into the school year designing and assembling two cube satellites.

Dube showed the students how to use computer-aided design software to develop specifications. He took them to the Quad-M facility to show them how the small satellite components are made.

Using their schematics, the company’s machinists and others helped the students create two reflector-covered, simple-but-functional CubeSats, as they are called in the aeronautics industry.

Because Quad-M makes devices that deploy CubeSats into space, when Dube learned that one of its dispensers scheduled for an orbital flight wasn’t full, he got one of the students’ CubeSats on board.

McDade residents raised money to help the students and their parents travel to Florida’s Cape Canaveral to see their creation launch in December 2018. It was a cloud-nine field trip.

When the high schoolers learned what the middle school students had built, they wanted in on the spaceflight action. So Dube repeated the program, allowing three interested high school students to build their own CubeSat and travel to Florida to see its launch. Dube died in January 2022 at 80.

“Assembling the satellite was a cool experience — seeing it all come together with everyone,” Colby Miller said. Now he is 14, and more interested in playing basketball and being a teenager, his father said, “but he’s also interested in architecture now, in designing and building something.”

More aerospace businesses in the Bluebonnet region

By Alyssa Meinke

QUAD-M ISN’T the only company in the Bluebonnet Electric Cooperative service area with aerospace-related missions. Within a 100-mile radius of the small McDade-area business are three other space technology companies.

X-Bow Systems Inc., which makes solid rocket motors and defense technologies, announced earlier this year the opening of a rocket manufacturing campus 4 miles north of Luling in Caldwell County.

The campus is being built on a portion of land that was previously Caldwell County Carter Memorial Airport. The company also plans to use land nearby on FM 2984. X-Bow has announced it plans to invest $25 million to develop 150 acres on which it will build, manufacture and test rockets on the properties. The company also promises the facility will bring dozens of jobs to the area.

Development of the Caldwell County facility began last year and is expected to be finished in the next two years. The site is already in use with a completed hangar and multiple rocket test pads. Using 3D-printed materials, X-Bow creates solid-fuel rocket motors and launch vehicles for national defense labs and a U.S. Department of Defense agency. Solid rocket engines are used as boosters to launch satellites or other objects on orbital and suborbital flights. The company also manufactures propellants and motors, and offers launch services.

The New Mexico-based company, founded in 2016, touts its innovative, cost-effective products. It also has facilities in Alabama, California, Colorado and Washington, D.C.

Another aerospace industry manufacturer that has operated in the Bluebonnet region for decades is HDL Research Lab in Brenham, in Washington County. The company, which manufactures electronics for converting power voltage for use in military defense aerospace applications, was founded in 1973 by Heinz D. Lichtenberg. Its products are used in radars, digital instrument panels, guidance systems and electronic warfare systems. The Brenham-based business worked with NASA to supply products for NASA’s Lidar In-Space Technology Experiment, which studied Earth’s atmosphere and global climate, and was launched in space in September 1994. Since then, it is focused primarily on products for aircraft and spacecraft for the Department of Defense.

The company is now run by Lichtenberg’s son, Kai Lichtenberg, and employs more than 130 people in its 88,000-square-foot facility, where staff design and manufacture its products, a mile north of downtown Brenham.

The third aerospace industry business in the Bluebonnet region is SpaceX (Space Exploration Technologies Corp.), the well-known rocket manufacturer/launcher and satellite communications company owned by Elon Musk. According to a job posting and comments from a SpaceX representative at a public meeting, SpaceX plans to use its Bastrop County-based facility to manufacture equipment for Starlink, its affiliated satellite-based broadband internet system.

In an unassuming building amid farmland near McDade, the small manufacturing company Quad-M is creating high-flying systems for use in space.